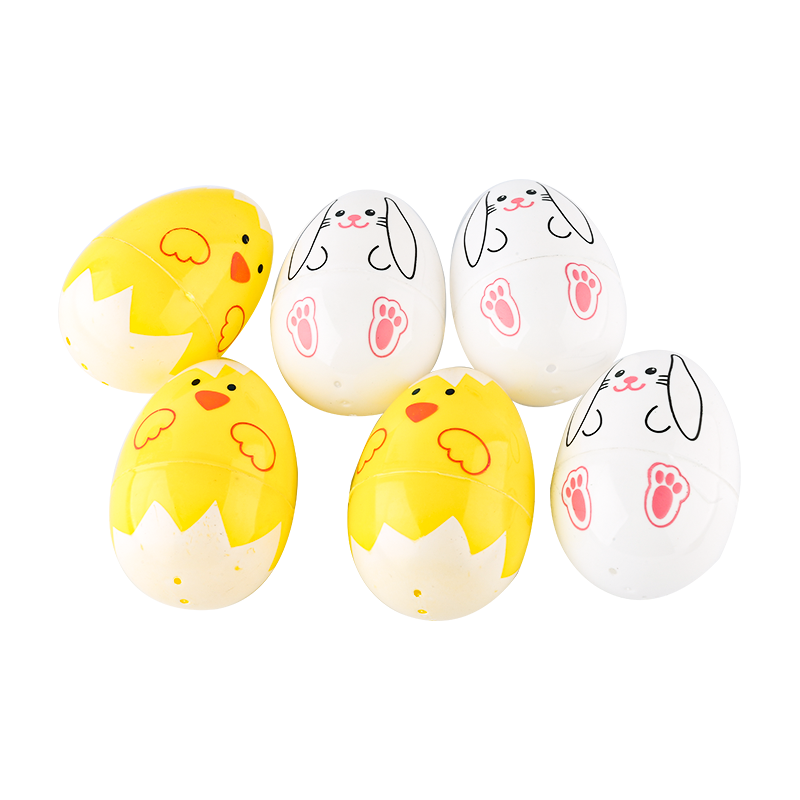

OEM PS Shaped Easter Egg

Product Category

PS Plastic Heterosexual Eggs

PS Plastic Shaped Egg Manufacturers

It is made of food-grade PS plastic by injection molding. It is not easy to deform, not easy to crush, smooth and transparent surface. Healthy and environmentally friendly, solid and durable, can hold candy, children's food packaging, jewelry storage, gift packaging, etc., transparent and round color, make small objects beautiful, beautiful and easy to keepOur plastic Easter eggs are made usingthick plastic in bright colors that are perfect for livening up your Easter baskets or being spotted by little ones during an Easter egg hunt. Each of our empty Easter eggs features a custom-designed hinge and super seal that makes them virtually pop-proof.They also includesafetu holes to prevent choking and are 100%recyclable.Choose from a variety of colors and sizes to coordinate with your Easter décor

PS Plastic Heterosexual Eggs Industry Knowledge Extension

What Are The Characteristics Of PS Plastic Shaped Easter Eggs?

PS plastic (polystyrene) is a common plastic material. It has the characteristics of high transparency, good hardness, and strong processing performance. It is often used to make various plastic products, including special-shaped Easter eggs. The following are the characteristics of PS plastic shaped Easter eggs:

1. Special-shaped design: Because PS plastic is easy to process and shape, it can be used to make Easter eggs of various shapes, not only traditional oval eggs, but also rabbit, chicken, rainbow, and flower shapes And other interesting special-shaped easter eggs.

2. Transparency: PS plastic has good transparency, so that the special-shaped Easter eggs can see the inner egg decoration through the appearance, which increases the artistic effect of the eggs.

3. Decorative: The surface of PS plastic is smooth, and various colorful patterns, decorations and stickers can be easily added to make the special-shaped Easter eggs more beautiful and attractive.

4. Lightweight and durable: PS plastic is a light and strong material, which makes the shaped Easter eggs very durable and can be used many times.

5. Affordable: PS plastic usually has a lower cost compared to other materials, so shaped Easter eggs are an affordable option.

6. Customizability: Since PS plastic is easy to process, it can be customized according to the needs of customers to create unique shaped Easter eggs.

The special-shaped Easter eggs made of PS plastic have the characteristics of unique design, good transparency, strong decoration and low cost, and they can add more fun and decorative effects to Easter celebrations. Whether used for family celebrations, school events or commercial venues, these shaped eggs are sure to be eye-catchers.

What Standards Does Food-Grade Plastic Easter Egg Meet?

To ensure food safety and hygiene, plastic easter eggs need to comply with specific food safety standards and regulations. Here are some common requirements and standards:

1. Food-grade materials: plastic easter eggs must be made of plastic materials that meet food-grade standards, such as food-grade polypropylene (PP) or food-grade polystyrene (PS), to ensure that the materials will not pollute food.

2. No harmful substances: food-grade plastic easter eggs cannot contain any substances harmful to human health, such as heavy metals, toxic substances, etc.

3. Antibacterial properties: food-grade plastic easter eggs should have certain antibacterial properties to keep food hygienic and safe.

4. High temperature resistance: Plastic Easter Egg needs to have high temperature resistance when in contact with food, so as to ensure that the heating and cooling process of food will not affect the performance and safety of eggs.

5. Hardness and wear resistance: food-grade plastic easter eggs should have sufficient hardness and wear resistance to prevent breakage and scratches during food loading and transportation.

6. Safe packaging: food-grade plastic easter eggs need to have a safe packaging design to ensure that the food inside the egg will not leak out or be contaminated.

7. Health certification: Manufacturers of food-grade plastic easter eggs usually need to obtain relevant health certification and food safety certification to ensure that the product meets national and international food safety standards.

8. Hygienic inspection: food-grade plastic easter eggs need to undergo hygienic inspection during the production process to ensure that the product meets relevant food safety standards.

These standards and requirements are all to ensure that food will not be contaminated when it comes into contact with food-grade plastic easter eggs, so as to protect the health and safety of consumers. When purchasing food-grade plastic easter eggs, it is advisable to choose a reputable manufacturer and seller to ensure that the product complies with food safety standards.

quick links

Contact Us

-

+86-576-89824666

+86-576-89824666

-

+86-576-84350990

+86-576-84350990

-

+86-15257601666(Crystal Yu)

+86-15257601666(Crystal Yu)

+86-15267666581(Carrie Tian) -

sales@tzchenye.com

sales@tzchenye.com

Aaddress

- Building 10 NO.148 Yongda Road, Jiangkou Street, Huangyan District, Taizhou, Zhejiang, China.

Mobile Site

Copyright 2022 Taizhou Chenye Plastic Co., Ltd, All Rights Reserved

Food-Grade Plastic Easter Egg Suppliers

Food-Grade Plastic Easter Egg Suppliers

En

En  English

English русский

русский