As the Easter season approaches, the production of Easter eggs takes center stage in the confectionery industry. The tradition of Easter eggs dates back centuries, symbolizing new life and rebirth. However, with growing environmental concerns, the industry is facing the challenge of balancing this cherished custom with the need to reduce plastic waste and promote sustainability. This article explores the efforts being made to address the issue of plastic in Easter egg production and the innovative solutions being adopted by manufacturers.

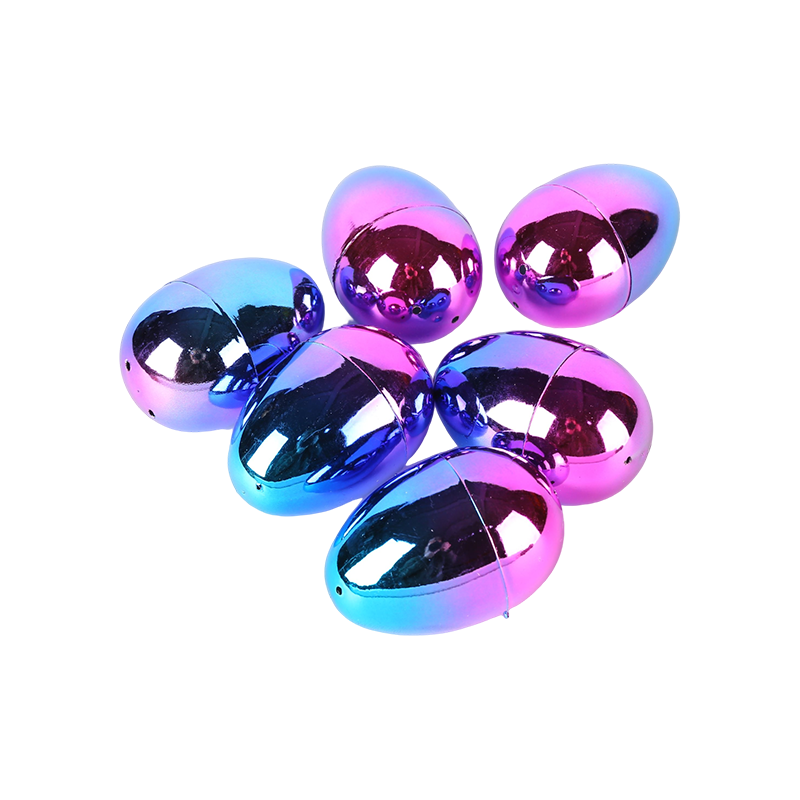

The Easter egg, a staple of the holiday, is often encased in plastic to ensure it reaches consumers in pristine condition. However, the ubiquity of plastic packaging has led to significant environmental issues, including pollution and the degradation of ecosystems. The phrase "Easter eggs plastic" has become a buzzword in discussions about the environmental impact of this seasonal product.

Manufacturers are now seeking alternatives to traditional plastic packaging. One such alternative is biodegradable or compostable materials, which break down naturally over time, reducing the environmental footprint. Companies are experimenting with materials like cornstarch, sugarcane, and even mushrooms to create packaging that is both functional and eco-friendly.

Another approach is to reduce the amount of packaging used. Some manufacturers are opting for minimal packaging or reusing existing packaging materials. This not only cuts down on waste but also sends a message to consumers about the company's commitment to sustainability. The phrase "Easter eggs plastic" is being replaced with "Easter eggs eco-friendly" in marketing materials as companies strive to align their products with consumer values.

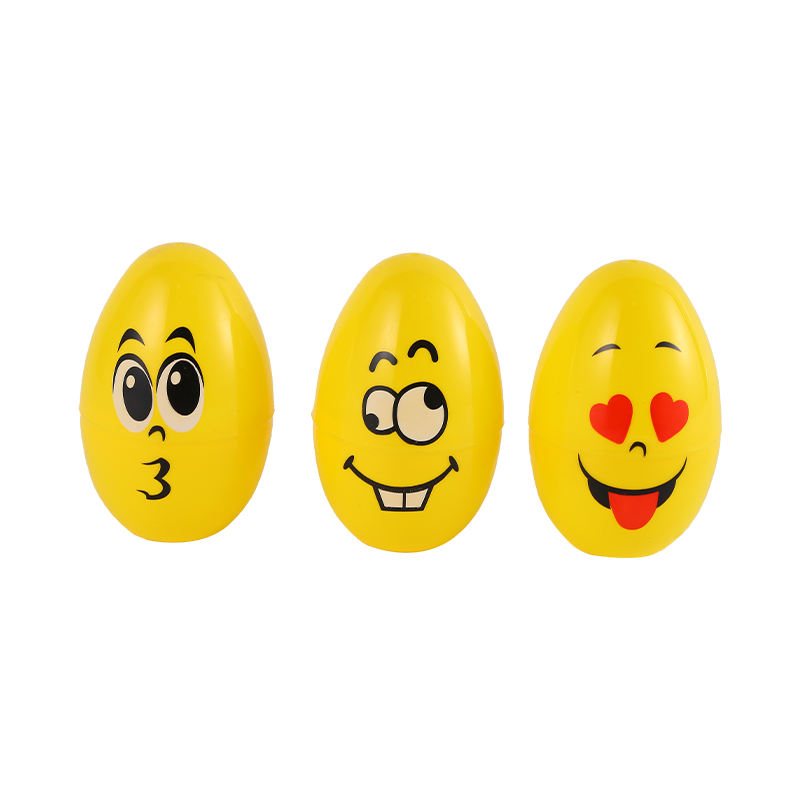

Innovation is also playing a role in addressing the issue of plastic in Easter egg production. Some companies are developing edible coatings for Easter eggs, eliminating the need for plastic wrapping altogether. These coatings can be made from natural ingredients and are not only environmentally friendly but also add a unique touch to the product.

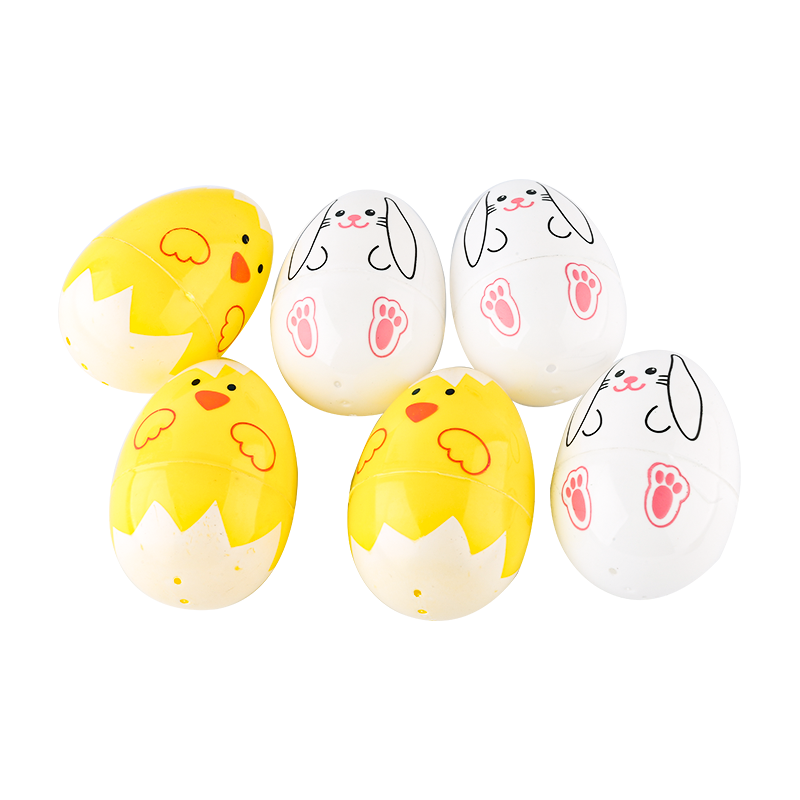

Consumer awareness and behavior are also driving change in the industry. As more people become conscious of the environmental impact of their purchases, there is a growing demand for products that are both traditional and sustainable. This has led to an increase in the popularity of artisanal Easter eggs, which are often made with natural ingredients and wrapped in recyclable or biodegradable materials.

The role of government and regulatory bodies cannot be overlooked. Policies and regulations are being put in place to encourage or mandate the reduction of plastic used in packaging. This includes incentives for companies that adopt sustainable practices and penalties for those that do not.

Education is another key factor in the shift towards environmentally friendly Easter egg production. Manufacturers are investing in campaigns to educate consumers about the importance of recycling and the benefits of choosing products with less plastic. This includes clear labeling on packaging to inform consumers about the materials used and how to dispose of them properly.

Collaboration between different stakeholders is also proving to be effective. Manufacturers, retailers, and environmental organizations are working together to find solutions to the plastic problem. This includes sharing better practices, conducting research, and developing industry standards for sustainable packaging.

The impact of these efforts is already being felt. There is a noticeable trend towards more sustainable Easter egg production, with many companies making significant strides in reducing their use of plastic. The phrase "Easter eggs plastic" is gradually being replaced with terms like "Easter eggs sustainable" and "Easter eggs eco-packaging" as the industry moves towards a greener future.

However, challenges remain. The cost of developing and implementing sustainable packaging solutions can be high, and not all companies may be able to afford these changes. Additionally, consumer habits are slow to change, and some may still prefer the convenience of traditional plastic packaging.

In conclusion, the confectionery industry is at a crossroads when it comes to Easter egg production. The tradition of giving and receiving Easter eggs is deeply ingrained, but so too is the need to protect our environment. By embracing innovation, reducing plastic use, and promoting sustainability, the industry can ensure that the joy of Easter eggs is preserved for future generations while also contributing to a healthier planet. The phrase "Easter eggs plastic" will hopefully become a relic of the past, replaced by a new era of environmentally conscious Easter egg production.

En

En  English

English русский

русский